Diagnostics & Lab-on-a-Chip

Where precision meets possibility.

Choose laser for diagnostics & lab-on-a-chip.

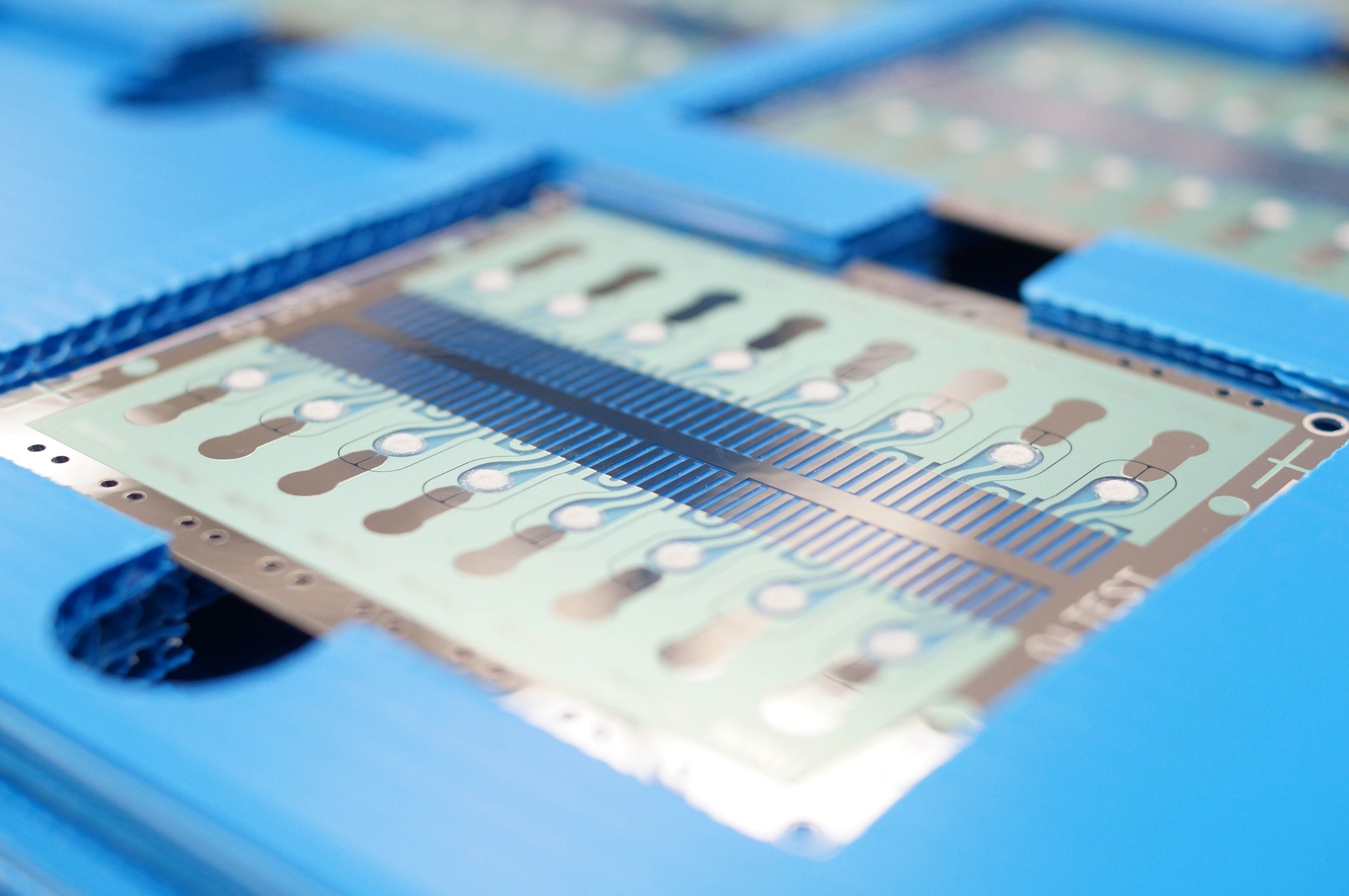

Traditional manufacturing methods often struggle to produce the fine details required in the laboratory and diagnostic testing industry. In contrast, laser technology enables the creation of intricate features and high-resolution details that are difficult or impossible to achieve with conventional techniques.

Achieve High Precision on a Variety of Materials

Accelerate Product Design Process

Rapidly Prototype Without Tooling Changes

The LasX Advantage

-

Unmatched laser expertise.

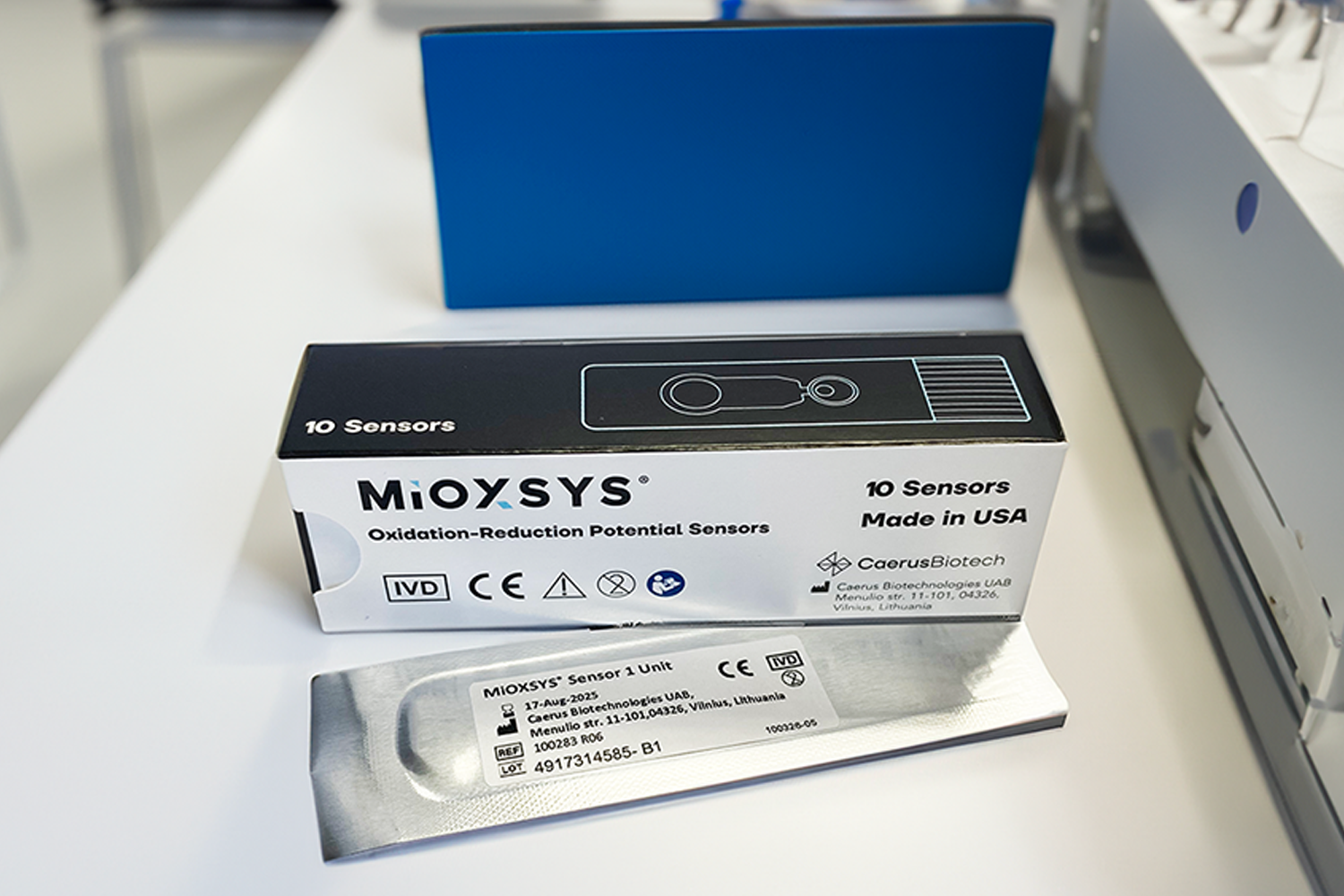

LasX’s USA-based ISO 13485-certified facility is equipped with multiple laser processing stations and cleanrooms—facilitating the rapid delivery of medical components with minimal setup required.

Our advanced technology delivers features as small as 50µm, surpassing the limits of traditional manufacturing. It scales from 10 to millions of parts with laser processing speeds 10 to 50 times faster than fixed beam systems.

-

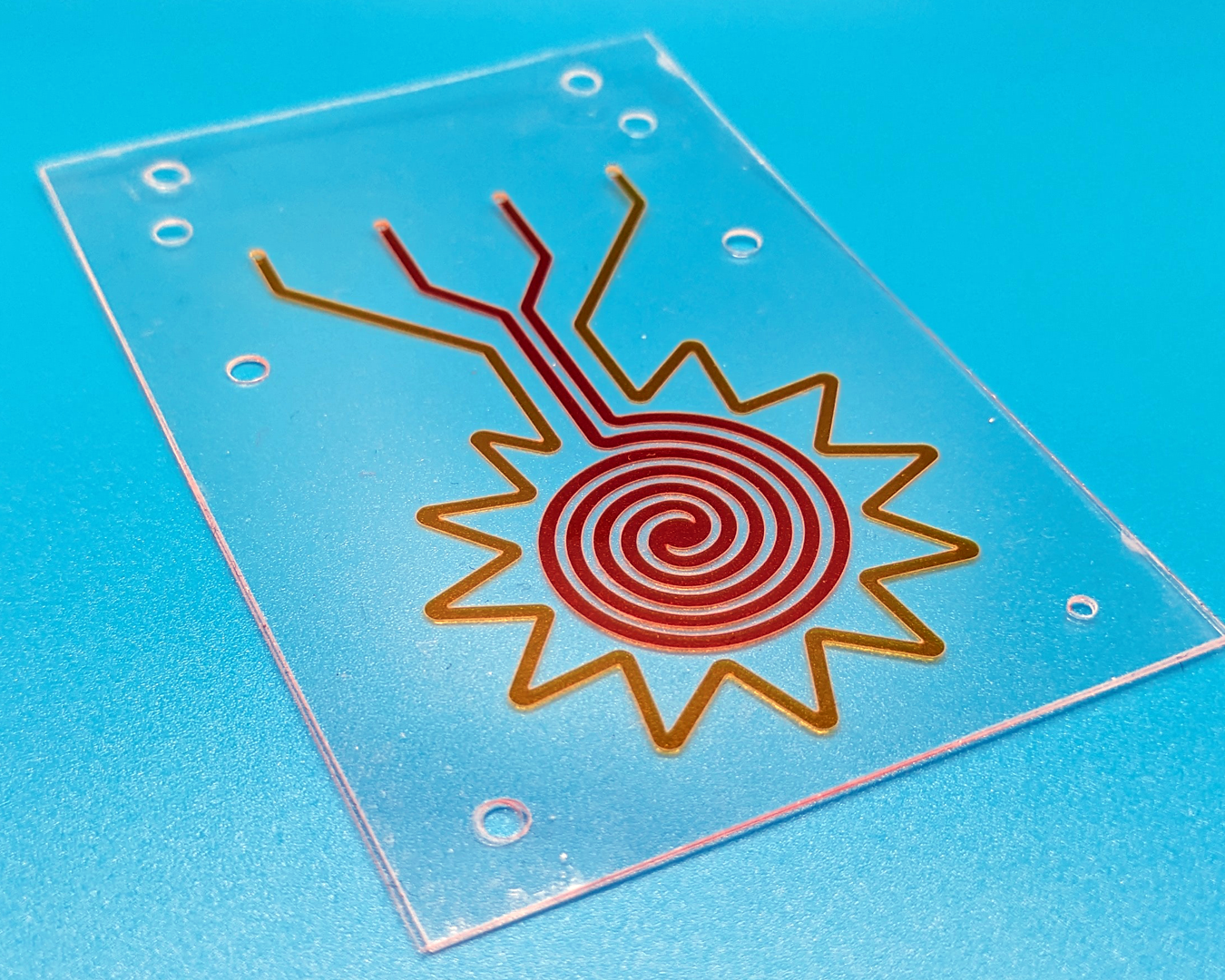

Dedicated life sciences division.

At the forefront of medical device innovation, MicroMed Solutions is LasX’s dedicated life sciences division—specializing in microfluidic technology and thin-film laser converting to bring point-of-care devices to market.

Our team supports clients from product development to high volume commercial production, backed by ISO 13485 certification and a deep understanding of medical device innovation.

Featured technology

Material Formats

Roll Fed

Sheet Fed

Solutions designed around you

-

Contract Manufacturing Services

We deliver intricate medical components with a confidential, quality-driven manufacturing approach.

-

Custom Equipment Development

LasX designs laser systems tailored to the automation and processing needs of lab-on-a-chip applications.

-

Design & Development Services

Our dedicated division helps labs, universities, biotech innovators, and medical firms turn prototypes into manufacturable devices.

Sucess stories from LasX